Walking Beam Reheating Furnace/walking beam type reheating furnace

Walking Beam Reheating Furnace/walking beam type reheating furnace

- However, some specifications of a typical walking beam type reheating furnace are:

- Temperature range: Walking Beam Reheating Furnaces can reach temperatures of up to 1300°C.

- Capacity: The capacity of a walking beam type reheating furnace can vary from a few tons up to several hundred tons, depending on the size and type of steel products being reheated.

- Fuel type: These furnaces typically use natural gas, propane, or other fuels as their primary source of heat.

- Conveyor system: Walking Beam Reheating Furnaces use a walking beam conveyor system to transport steel products through the heating chambers. The conveyor system is designed to provide precise and controlled movement of the products through the furnace.

- Heating chambers: These furnaces are equipped with multiple heating chambers, each of which is lined with refractory materials to withstand the high temperatures generated during the heating process.

Description

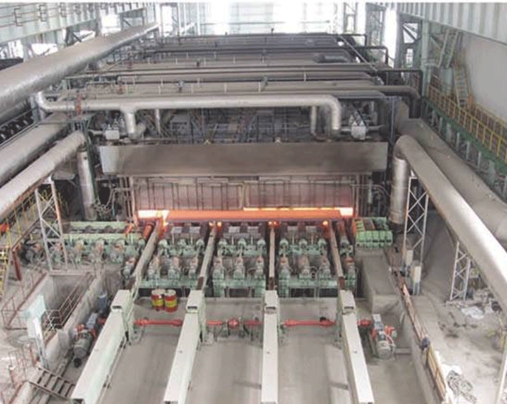

A Walking Beam Reheating Furnace, also known as a walking beam type reheating furnace, is a type of furnace used in the steel industry for the reheating of steel billets, blooms, slabs, and other steel products before they are rolled or forged.

The furnace consists of a series of refractory-lined heating chambers, where the steel products are placed on a walking beam conveyor system that moves them through the furnace. The walking beam system supports the steel products and moves them forward in a controlled manner, ensuring that they are heated evenly and consistently.

The furnace is heated using natural gas, propane, or other fuels, and can reach temperatures of up to 1300°C. The heated steel products are then removed from the furnace and transported to the rolling or forging mill where they are further processed into finished steel products. Walking Beam Reheating Furnaces are known for their high efficiency and reliability, and are widely used in the steel industry for their ability to provide consistent and uniform heating of steel products.

Working principle: Walking Beam Reheating Furnace

The working principle of a Walking Beam Reheating Furnace is based on the principle of convection and radiation heating. The furnace is designed to provide a controlled and consistent heating environment for steel products by utilizing a walking beam conveyor system that moves the products through the furnace in a continuous and uniform manner.

When the steel products are loaded onto the walking beam conveyor system, they are transported through a series of refractory-lined heating chambers. The chambers are heated using natural gas or other fuels, and the heat is transferred to the steel products through a combination of convection and radiation.

As the steel products move through the furnace, they are exposed to a high-temperature environment that causes them to heat up and reach the desired temperature. The walking beam conveyor system ensures that the steel products are moved through the furnace in a controlled and consistent manner, allowing them to be heated evenly and ensuring that they reach the desired temperature.

Once the steel products have been heated to the desired temperature, they are removed from the furnace and transported to the rolling or forging mill where they are further processed into finished steel products.

The characteristics

Some of the main characteristics of a Walking Beam Reheating Furnace include:

- Efficient heating: Walking Beam Reheating Furnaces are designed to provide efficient and consistent heating of steel products. The walking beam conveyor system ensures that the steel products are heated evenly, reducing the risk of overheating or underheating.

- High temperature capability: These furnaces can reach temperatures of up to 1300°C, making them suitable for reheating a wide range of steel products.

- Reliable operation: Walking Beam Reheating Furnaces are known for their reliability and long service life. They are designed to withstand the harsh conditions of the steel industry, and are built using high-quality materials and components.

- Automation: Many modern Walking Beam Reheating Furnaces are equipped with advanced automation systems, which allow for precise control over the heating process. This helps to reduce the risk of errors and ensures consistent and reliable operation.

- Customizable design: Walking Beam Reheating Furnaces can be customized to meet the specific needs of different steel products and production processes. This makes them a versatile and adaptable solution for a wide range of applications in the steel industry.